Methoxyflurane Production Cost Analysis Report: Comprehensive Assessment and Key Insights

The latest report on Methoxyflurane production by Procurement Resource offers an in-depth analysis of the cost structure and production processes involved in the manufacture of this crucial anesthetic agent. This report serves as a valuable resource for stakeholders looking to understand the economic dynamics and intricacies of Methoxyflurane production, thereby enabling informed decision-making and strategic planning.

Request For Free Sample: https://www.procurementresource.com/production-cost-report-store/methoxyflurane/request-sample

Procurement Resource Assessment of Methoxyflurane Production Process

Procurement Resource provides a thorough assessment of the Methoxyflurane production process, focusing on various methods employed in the industry. The analysis includes a detailed examination of the key stages of production, from raw material procurement to the final product. Each stage is scrutinized to identify cost factors and optimize efficiency. The assessment also covers potential technological advancements and innovations that could streamline production and reduce costs.

Product Definition

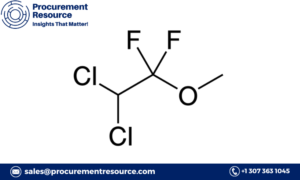

Methoxyflurane is a volatile, fluorinated hydrocarbon that has been widely used as an inhalational anesthetic agent. Known for its potent analgesic properties, Methoxyflurane is administered via inhalation and is particularly valued in emergency medicine and pre-hospital care settings for its ability to provide rapid pain relief. The compound’s chemical formula is C3H4Cl2F2O, and it is known for its distinctively sweet smell. Despite its powerful anesthetic effects, Methoxyflurane is used with caution due to its potential nephrotoxic effects at higher doses.

Market Drivers

The demand for Methoxyflurane is driven by several key factors:

- Increasing Demand in Emergency Medicine: Methoxyflurane’s rapid onset of analgesic action makes it highly valuable in emergency medical situations, including trauma and pre-hospital care, where quick pain relief is crucial.

- Advancements in Medical Technology: Innovations in delivery mechanisms and formulations have enhanced the efficacy and safety profile of Methoxyflurane, boosting its adoption in various medical settings.

- Rising Healthcare Expenditure: With increasing global healthcare spending, there is a growing emphasis on improving patient outcomes and experiences, driving demand for effective analgesic solutions like Methoxyflurane.

- Growing Awareness and Acceptance: Increased awareness among healthcare professionals about the benefits of Methoxyflurane, coupled with favorable regulatory approvals, has contributed to its expanding market.

Raw Materials Requirements

The production of Methoxyflurane involves several critical raw materials, each contributing to the overall cost and quality of the final product:

- Chloroform: Used as a precursor in the synthesis process, chloroform is a key raw material whose quality and purity directly impact the efficiency of Methoxyflurane production.

- Hexafluoroacetone: This fluorinated compound is another essential raw material, contributing to the unique chemical properties of Methoxyflurane.

- Other Reagents and Solvents: Various other chemicals and solvents are required during the synthesis process to facilitate reactions and purify the product.

Ensuring a reliable supply of high-quality raw materials is crucial for maintaining consistent production standards and optimizing costs.

Costs and Key Process Information

The cost structure of Methoxyflurane production is influenced by several factors, including raw material costs, labor, energy consumption, and technological investments. Procurement Resource’s analysis breaks down these costs into detailed components, providing insights into the financial aspects of Methoxyflurane manufacturing.

- Raw Material Costs: These constitute a significant portion of the overall production cost. Variations in the market prices of chloroform and hexafluoroacetone can substantially impact the production budget.

- Labor Costs: Skilled labor is essential for handling the sophisticated chemical processes involved in Methoxyflurane production. Labor costs vary based on the location and scale of production facilities.

- Energy Costs: The synthesis and purification processes require substantial energy input, making energy costs a critical factor in the overall cost structure.

- Technology and Equipment Costs: Investment in advanced technology and high-quality equipment can enhance production efficiency but also adds to the initial setup costs.

- Regulatory Compliance: Adhering to stringent regulatory standards for pharmaceutical production involves additional costs related to quality control, testing, and certification.

Looking for an Exhaustive and Personalized Report That Could Significantly Substantiate Your Business?

For businesses seeking to delve deeper into the intricacies of Methoxyflurane production, Procurement Resource offers exhaustive and customized reports tailored to specific needs. These reports provide comprehensive insights into cost dynamics, market trends, and strategic opportunities, empowering businesses to make data-driven decisions and optimize their operations.

Procurement Resource’s expertise in cost analysis and market assessment ensures that the reports are detailed, accurate, and actionable. By leveraging these insights, businesses can enhance their production efficiency, reduce costs, and gain a competitive edge in the market.

In conclusion, the Methoxyflurane Production Cost Analysis Report by Procurement Resource is an invaluable tool for stakeholders looking to understand and optimize the production process of this essential anesthetic agent. With detailed assessments of raw material requirements, cost structures, and market drivers, the report equips businesses with the knowledge needed to thrive in the competitive pharmaceutical landscape. For an exhaustive and personalized analysis that can substantiate your business strategy, Procurement Resource’s Methoxyflurane report is the definitive guide.

Contact Us:

Company Name: Procurement Resource

Contact Person: Christeen Johnson

Email: [email protected]

Toll-Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA