What Are the Different Types of Hot Rolled Plates?

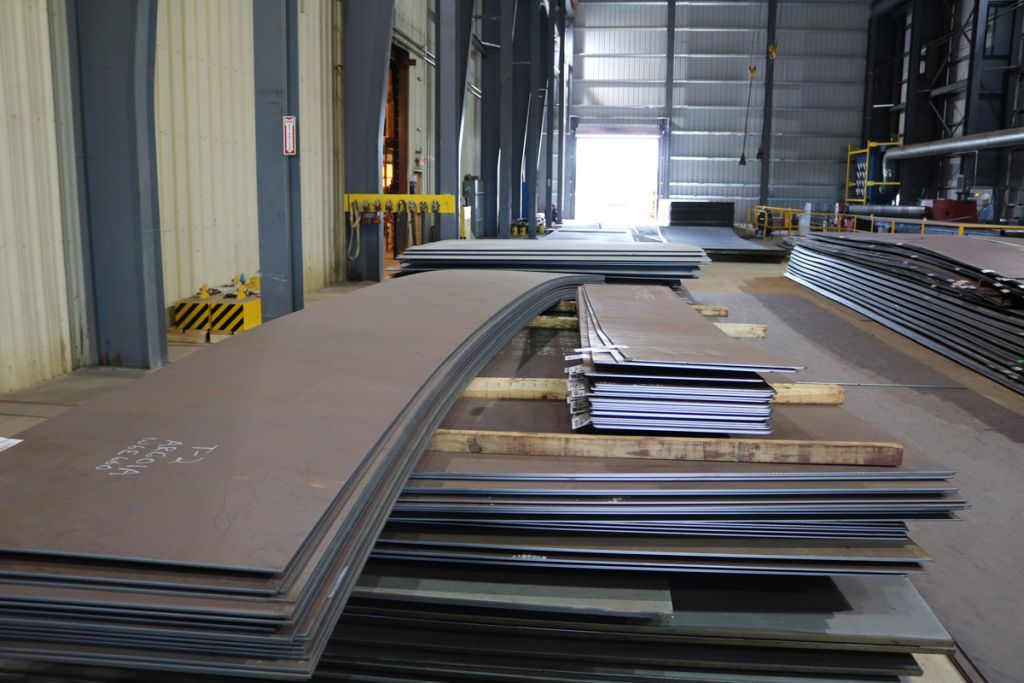

When it comes to construction and manufacturing, hot rolled plates are a common material used in various applications. These plates are made by rolling steel at high temperatures, which makes them easy to shape and form. In this blog, we will explore the different types of hot rolled plates, their uses, and what you need to know before purchasing them. This guide will help you make an informed decision, whether you’re a contractor, engineer, or simply someone interested in learning more about this versatile material.

Introduction to Hot Rolled Plates

Hot rolled plates are a type of steel plate produced by heating steel above its recrystallization temperature and then rolling it into the desired shape. This process makes the steel easier to shape and results in a product that is ideal for various industrial applications.

What Is Hot Rolling?

Hot rolling is a metalworking process that involves rolling steel at a temperature above its recrystallization point, which is typically over 1700°F (926°C). This high temperature makes the steel more malleable and easier to shape. After the steel is rolled into the desired shape, it is cooled at room temperature. The result is a plate that has a rougher surface and less precise dimensions compared to cold rolled steel, but it is also more affordable and easier to produce in large quantities.

Note – Are you ready to find the perfect hot rolled plates for your next project? Don’t wait any longer! Explore our extensive selection of high-quality hot rolled plates today and get the best material for your construction, manufacturing, or industrial needs. Contact us now to learn more and place your order. Experience the strength and versatility of hot rolled plates with us!

Benefits of Hot Rolled Plates

Hot rolled plates offer several advantages:

- Cost-Effective: They are generally cheaper to produce than cold rolled plates.

- Versatility: They can be used in a wide range of applications, from construction to manufacturing.

- Ease of Production: The high temperature makes the steel easier to work with, allowing for faster production times.

- Strength: Despite the rough surface, hot rolled plates are strong and durable, making them suitable for heavy-duty applications.

Different Types of Hot Rolled Plates

There are several types of hot rolled plates, each with its own unique properties and uses. Understanding these types can help you choose the right plate for your specific needs.

Mild Steel Plates

What Are Mild Steel Plates?

Mild steel plates are the most common type of hot rolled plates. They are made from low carbon steel, which makes them more ductile and easier to work with than higher carbon steels. This type of steel is also known for its good weldability and machinability.

Uses of Mild Steel Plates

Mild steel plates are used in a variety of applications, including:

- Construction: Used in the construction of buildings, bridges, and other structures.

- Manufacturing: Utilized in the production of machinery, automotive parts, and appliances.

- Fabrication: Employed in the creation of various metal products, such as frames and supports.

Advantages of Mild Steel Plates

- Affordable: Mild steel is one of the most cost-effective types of steel.

- Easy to Work With: Its ductility makes it easy to cut, bend, and weld.

- Versatile: Can be used in a wide range of applications.

Carbon Steel Plates

What Are Carbon Steel Plates?

Carbon steel plates are made from steel with a higher carbon content compared to mild steel. This results in a harder and stronger material, but it also makes the steel less ductile and more challenging to work with.

Uses of Carbon Steel Plates

Carbon steel plates are used in applications that require higher strength and durability, such as:

- Construction: Suitable for building heavy-duty structures like bridges and skyscrapers.

- Manufacturing: Used in the production of heavy machinery and equipment.

- Automotive: Employed in making car parts that require high strength.

Advantages of Carbon Steel Plates

- High Strength: Offers greater strength and durability compared to mild steel.

- Wear Resistance: More resistant to wear and tear, making it ideal for heavy-duty applications.

- Longevity: Longer lifespan due to its toughness.

High-Strength Low-Alloy Steel Plates

What Are High-Strength Low-Alloy Steel Plates?

High-strength low-alloy (HSLA) steel plates are made by adding small amounts of alloying elements, such as chromium, copper, and nickel, to the steel. These elements improve the strength and toughness of the steel without significantly increasing its weight.

Uses of High-Strength Low-Alloy Steel Plates

HSLA steel plates are used in applications that require both high strength and low weight, such as:

- Construction: Ideal for constructing high-rise buildings and large infrastructure projects.

- Automotive: Used in the production of lightweight yet strong car components.

- Shipbuilding: Employed in the construction of ships and offshore platforms.

Advantages of High-Strength Low-Alloy Steel Plates

- Strength-to-Weight Ratio: Offers high strength without adding excessive weight.

- Corrosion Resistance: Alloying elements improve resistance to corrosion.

- Toughness: Maintains good toughness even at low temperatures.

Abrasion-Resistant Steel Plates

What Are Abrasion-Resistant Steel Plates?

Abrasion-resistant (AR) steel plates are designed to withstand wear and tear better than other types of steel. They are made by adding alloying elements like carbon and manganese, which increase the hardness of the steel.

Uses of Abrasion-Resistant Steel Plates

AR steel plates are used in applications where the material will be subject to a lot of wear and tear, such as:

- Mining: Used in the construction of mining equipment and machinery.

- Construction: Employed in building structures that experience high abrasion.

- Manufacturing: Used in making industrial equipment and tools that require high durability.

Advantages of Abrasion-Resistant Steel Plates

- High Hardness: Offers superior resistance to wear and tear.

- Durability: Long-lasting even in harsh environments.

- Low Maintenance: Requires less maintenance due to its toughness.

Weathering Steel Plates

What Are Weathering Steel Plates?

Weathering steel plates, also known as corten steel, are made to resist corrosion and rust. They contain alloying elements like copper, chromium, and nickel, which form a protective oxide layer on the surface of the steel.

Uses of Weathering Steel Plates

Weathering steel plates are used in applications that require a durable and corrosion-resistant material, such as:

- Architecture: Used in building facades and sculptures for their aesthetic appeal.

- Bridges: Employed in the construction of bridges due to their durability and low maintenance.

- Marine: Used in marine structures that are exposed to harsh weather conditions.

Advantages of Weathering Steel Plates

- Corrosion Resistance: Forms a protective layer that prevents rust and corrosion.

- Aesthetic Appeal: Develops a unique, rustic appearance over time.

- Low Maintenance: Requires less maintenance due to its self-protecting properties.

Boiler and Pressure Vessel Steel Plates

What Are Boiler and Pressure Vessel Steel Plates?

Boiler and pressure vessel steel plates are designed to withstand high pressure and temperature conditions. They are made from high-quality steel that can handle extreme environments without losing strength.

Uses of Boiler and Pressure Vessel Steel Plates

These plates are used in the production of boilers, pressure vessels, and other equipment that operate under high pressure and temperature, such as:

- Power Plants: Used in the construction of boilers and other equipment in power plants.

- Petrochemical: Employed in making pressure vessels for storing and transporting chemicals.

- Manufacturing: Used in the production of high-pressure machinery and equipment.

Advantages of Boiler and Pressure Vessel Steel Plates

- High Strength: Can withstand high pressure and temperature without deforming.

- Durability: Long-lasting even in extreme conditions.

- Safety: Ensures the safe operation of boilers and pressure vessels.

Choosing the Right Hot Rolled Plate for Your Needs

Selecting the right hot rolled plate depends on various factors, including the specific requirements of your project, the environment in which the material will be used, and your budget. Here are some tips to help you make the right choice:

Determine Your Requirements

Identify the key requirements of your project, such as the need for high strength, corrosion resistance, or abrasion resistance. This will help you narrow down your options and choose a plate that meets your needs.

Consider the Environment

Think about the environment in which the material will be used. For example, if the material will be exposed to harsh weather conditions, you might want to choose weathering steel plates. If it will be subject to a lot of wear and tear, abrasion-resistant steel plates might be the best option.

Evaluate Your Budget

Consider your budget when selecting hot rolled plates. While some types of plates might be more expensive, they could offer better performance and longer lifespan, which can save you money in the long run.

Consult with Experts

If you’re unsure about which type of hot rolled plate to choose, consult with experts in the field. They can provide valuable insights and recommendations based on your specific needs and requirements.

Conclusion

Hot rolled plates are an essential material in many industries, offering a range of benefits and applications. By understanding the different types of hot rolled plates and their uses, you can make an informed decision and choose the right material for your project. Whether you need mild steel plates for a construction project, high-strength low-alloy steel plates for automotive parts, or abrasion-resistant steel plates for mining equipment, there is a hot rolled plate that will meet your needs.

For more insightful articles related to this topic, feel free to visit allguestblog.com